Thermal Management Solutions

Empowering Electronics Manufacturers

Diane Elliott

Diane Elliott

Engineering Sales Representative

Ellsworth Adhesives

Dan Strawn

Dan Strawn

Engineering Sales Representative

Ellsworth Adhesives

Rapid innovation in today’s electronics industry is driving smaller scale and higher speed goods, making circuit board cooling a primary challenge. This trend drives the demand for higher performance and more cost-effective thermal management solutions. The ability to manage the temperature of electronics has a direct impact on the reliability, quality, lifetime, and cost of the device.

Engineers have the benefit of an expanding selection of thermal interface materials (TIMs) and techniques, so impractical thermal management solutions can easily be avoided.

Types of Thermal Interface Materials

The operation of a circuit board largely determines the type of TIM and application technique. Manufacturers can choose from thermally conductive adhesives, compounds, greases, pastes, gels, pads, tapes, and encapsulants.

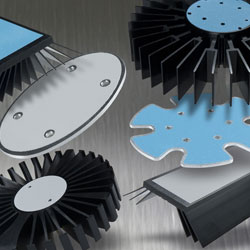

Thermally Conductive Adhesives

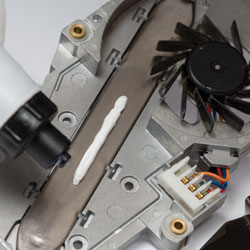

Thermally conductive adhesives permanently affix heat sinks to heat-generating components of a printed circuit board (PCB). One-part adhesives are easy-to-apply, but two-part epoxies are often stronger. No additional structures are required to secure the heat sink, and a minimal bond line thickness ensures a reliable bond without exceeding dimensional tolerances. Adhesives offer better conductance than thermal tapes, but do not convey heat as well as non-curing thermal compounds, though there is no risk of bleed-out or dry-out. Thermally conductive adhesives are not recommended for circuits that may need repairs or upgrades.

Non-Curing Thermal Compounds, Greases, Pastes & Gels

Non-curing materials consist of a thickened base liquid that has been filled with a thermally conductive material. They are quite viscous, which reduces the chance of bleed-out. Capillary action fills microscopic gaps between the heat sink and mounting surface to improve thermal transfer by reducing thermal resistance. Bleed-out and dry-out are the most notable drawbacks of thermal greases, making curing compounds more suitable when these factors are a concern.

Thermal Pads and Tapes

Best used for applications where a semi-permanent bond and short assembly times are priorities, thermal pads and tapes are easy to apply, do not need to cure, and are available in prefabricated dimensions. Thermal pads can be “dry,” meaning they contain no adhesive, or they may contain a pressure-sensitive adhesive that has lower bond strength than epoxies or adhesives.

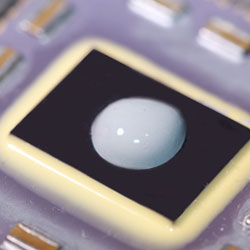

Thermal Encapsulants

Thermal encapsulants include two products: potting compounds, which cover an entire circuit, and glob tops, which cover a specific component or section of the circuit. These products provide protection from shock and vibration, environmental contaminants, and post-production alterations while electrically insulating the circuit. Potting compounds and glob tops are usually one or two-part compounds, and those that have been laden with filler material create a thermally dissipative and dielectric encapsulation.

Thermal Management Material Composition

The composition of most thermal interfaces can be viewed as two parts: base material and filler material Base materials are chosen for their dielectric strength, cure times, viscosity, and other mechanical properties directly relevant to the application. The sole purpose of filler material is heat transfer, and it is dispersed in a concentration sufficient to dissipate heat. However, high concentrations of filler material may be abrasive to the circuit and dispensing equipment.

Base Materials

- Silicones

- Polyurethanes

- Acrylics

- Mineral oils

- Ester oils

- Solders and fusible alloys such as gallium, tin, indium, lead, and/or bismuth

Filler Materials

- Metal powders: silver, aluminum, copper, zinc, and gold, and dissimilar metals.

- Metal oxides (ceramics) and metal nitrides (inorganics): beryllium oxide, aluminum oxide, zinc oxide, silica/silicon dioxide, boron nitride, aluminum nitride, and mixa.

- Carbon-based: diamond, carbon fiber, graphite, or graphene.

Ellsworth Adhesives provides a variety of thermal management products and is always looking for new technologies to make today’s electronics smaller, faster, and stronger. Top thermal management manufacturers include 3M, Bergquist, Dow, Henkel LOCTITE®, ResinLab, and Techspray.

To learn more about thermal management solutions, download the white paper.

Have questions on which material is right for your application? Ask the Glue Doctor® to connect with our experienced technical service team.