Why Glass Transition Temperature Matters in Electronic Encapsulation Applications

Tom Steucek

Tom Steucek

Engineering Sales Representative

Ellsworth Adhesives

What is glass transition temperature?

Adhesives are often expected to hold up under significant environmental stress. Heat poses unique challenges that can alter the chemistry and durability of a material. One attribute used to better understand what an adhesive can endure is glass transition temperature (Tg). Scientific journal

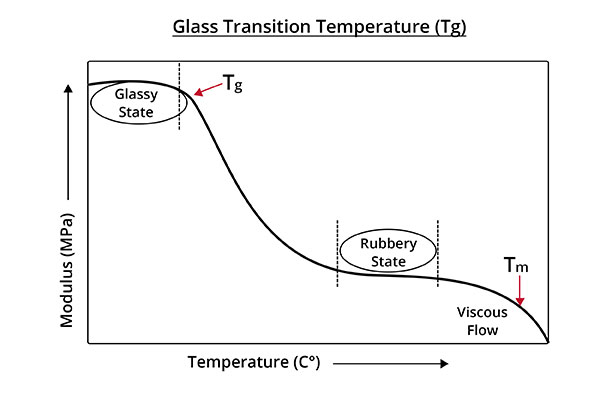

Nature Communications defines Tg as “the transition into a brittle glassy state, making [Tg an] accurate prediction for conjugated polymers crucial for the design of soft, stretchable, or flexible electronics.” It’s at this temperature, or more often temperature range, that the free volume (gap between the molecular chains) increases by 2.5 times. In short, knowing the glass transition temperature of a material indicates when the material changes from a rigid state to a more flexible state, and vice versa.

Achieving a high Tg often requires a heat cure and can be impacted by moisture, making temperature and humidity control an important part of the production process. Other attributes impacted by Tg include coefficient of thermal expansion (CTE), die shear, lap shear, and modulus.

How is glass transition temperature measured?

By observing how a material’s physical properties change across a particular temperature range, lab technicians can calculate Tg. There are a variety of available test methods, each with slight variations that can impact results. Using more than one method is common for quality control or research situations.

- Differential Scanning Calorimetry (DSC): Offered in heat flux or power differential

varieties, a sample and reference are compared at different levels of heat. - Dynamic Mechanical Analysis (DMA): A highly sensitive option, DMA applies sinusodial stress to a sample and monitors how it reacts.

- Thermal Mechanical Analysis (TMA): Using a mechanical probe, this test measures dimensional changes under controlled force, time, and temperature.

Working with an experienced lab is recommended, as they can identify the right test or combination of tests that best suit your application needs. ResinLab, a sister company of Ellsworth Adhesives, offers thermal analysis testing including glass transition temperature with both DSC and TMA methods.

Why is glass transition temperature important in electronic encapsulation?

Glass transition temperature plays an important role in the encapsulation process for a variety of industries. For example, an application that experiences extreme weather conditions will be subject to very hot or very cold temperatures, which can impact the strength of an adhesive bond. If a high degree of adhesion is desired at high temperatures, a polymeric system that provides a high Tg is the best option. The Tg is also important when considering the coefficient of thermal expansion (CTE). At the Tg, the coefficient of thermal expansion shifts from a lower value to a higher value. This expansion can lead to components on a circuit board being “popped” off of the board. Selecting a product with a Tg greater than the upper limit of an electronic part's thermal exposure can limit the likelihood of this occurring.

Similarly, electronic encapsulation sometimes requires Tg values below the lower limit of an electronic part's thermal exposure. These products tend to be softer and more pliable. Although they have higher CTE values, they generally lack the force required to break components off of a circuit board.

Electronic Encapsulation Application Examples:

- Downhole (Directional Drilling) Electronics: In the oil and gas industry, electronics are often used underground, subjecting them to extreme stress. Modems, magnets, control units, sensors, and other electronic systems can encounter temperatures 150 °C and higher, requiring thermal management techniques for reliable operation.

- Anti-lock Truck & Trailer Brake Systems (ABS): ABS systems use high Tg materials to encapsulate their electronics, which are often pelted with gravel during driving.

- Turbo Speed Sensors: Turbochargers compress airflow into a car’s engine to increase its power and speed. This process can produce high temperatures upwards of 250 °C, requiring the sensors to be encapsulated in a super high Tg material.

- Oil Pressure Sensors: Like turbo speed sensors, oil pressure sensors must be encapsulated in a high Tg material as they live inside engines which experience very high temperatures.

- Aircraft Wing Electronics: While printed circuit boards are typically enclosed in hermeticallysealed boxes within aircraft wings, the electronics are still exposed to extreme, rapidly changing temperatures during flight, requiring a compatible high Tg material.

Examples of Epoxies for Electronic Encapsulation:

| Manufacturer | Product Name | Glass Transition Temperature (Tg) |

| Henkel Loctite | STYCAST 2850GT | ≤111 °C (depending on hardner) |

| Parker Lord | Thermoset EP-830 | 175 °C |

| ResinLab | ResinLab EP1350 | 203 °C |

| ELANTAS PDG | Epoxylite® E 5302 | 230 °C |

How do I locate the glass transition temperature of a material?

Typically, the glass transition temperature will be located on a material’s technical datasheet (TDS) provided by the manufacturer. Ellsworth Adhesives offers a library of technical documentation including safety data sheets, technical data sheets, REACH, and RoHS documents for all products offered both on and offline. If the glass transition temperature is not provided in the technical documentation our team can reach out to the supplier for more detail, or coordinate with our sister company ResinLab® to perform lab tests for a more complete picture of the material.

What if I'm not sure which material is right for the job?

With a host of other chemical attributes to consider, sometimes an expert’s assistance is needed. The Ellsworth Adhesives team of Glue Doctors® draws from over 800 years of combined experience in chemical, electrical, mechanical, and aerospace engineering. They are equipped to help identify your application needs and select the right material.