Hot Melt Solutions For Assembly, Lamination, Packaging & More

Ellsworth Adhesives offers a wide range of hot melt formulas alongside the latest equipment and tools to support everything from bulk automated spray lamination to handheld applications.

You’ll often find hot melts in packaging, labeling, filters, laminates, textiles, and general industry. Their versatility means applications vary from performance gaskets to stacked foams and simple bonds.

With their fast-setting nature, hot melts simplify just-in-time production and streamline workflows. Their quick bond strength enables fast fixturing, so you can keep pieces moving down the line.

From pellets, sticks, and pillows to hot melt dispensing equipment, Ellsworth Adhesives is here to help you find the ideal chemistry and production model for your business. Our experts are ready to help from selection to testing and troubleshooting.

Quickly Bond & Seal without Hassles

Trying to speed up assembly with less clamping and fixturing hassles?

Create Precision Form-in-Place Gaskets

Looking for a faster, easier way to create custom-shaped gaskets?

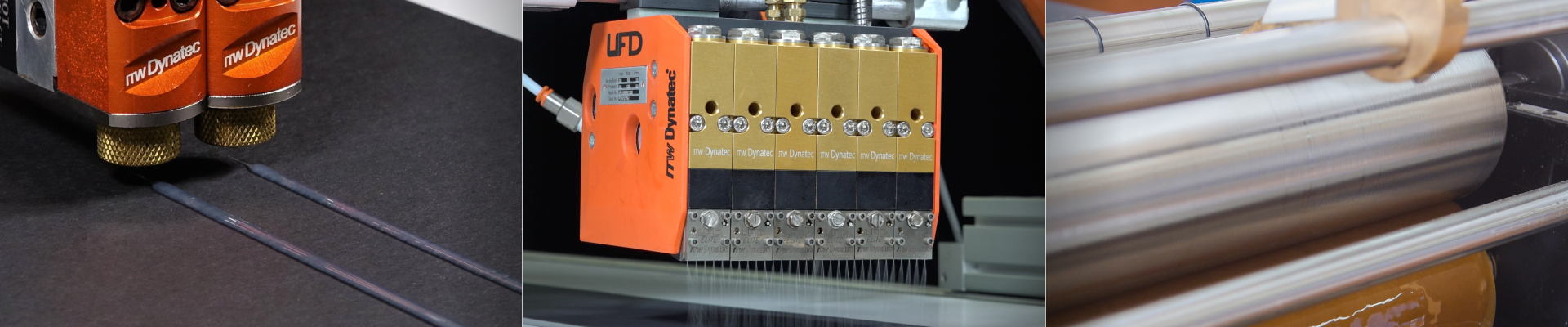

Easier Lamination with Non-Contact Systems

Tired of touching up bald spots on uneven substrates? Wasting time fishing fiberglass and wool from your roll coaters?

Complete Production Solutions

Unsure what the best hot melt tools, formulas and workflows are for your process?

Create a superior hot melt system with help from industry experts

Explore Hot Melt Formulas

Hot melts are commonly used for bonding, sealing, assembly, form-in-place gasketing, and more. Ellsworth Adhesives carries a wide range of formulas to help you tackle complex issues.

Hot melt manufacturers include: 3M, Bostik, Dow, Elemelt, HB Fuller, Henkel LOCTITE, Power Adhesives, REXtac, GDI

Common Hot Melt Formats

- Various length and width sticks

- Small pellets and pillows

Common Hot Melt Chemistries

- Pressure sensitive

- Polyamide

- APAO

- PUR

- EVA

Which Bulk Hot Melt System Works for You?

Whether you’re creating gaskets at small scale or spraying webs constantly, our range of bulk hot melt equipment offers a reliable solution. Options range from benchtop units using pellets to large floor stands that pump entire drums.

Production-Ready Adhesive Systems

Combine a benchtop hot melt adhesive supply unit with hoses, nozzles, and handheld applicators to create a workflow customized to your production line.

Systems can support low and medium volume operations with a variety of supply unit sizes and support equipment.

Large-Scale Pail and Drum Melters

For large-scale production set-ups, pail and drum melters offer uninterrupted flow and minimal downtime. Designed to supply hot melts, EVA, and PUR to support various applications.

Bulk melters offer temperature controls, various sensors, low volume indicators, self-diagnostics, and interchangeable platen faces for easy usage.

Easily pair with robotic dispensers, automated spray conveyers, or handheld systems to improve throughput and accuracy on nearly any production line.

Explore Handheld Dispensing Options

When bulk production models don’t support your scale, but hot melts still offer a strong solution, you can turn to handheld applicators for a variety of challenges.

They can dispense in beads, lines, dots, or spray patterns, and are best for low to high volume production. Available in manual and pneumatic power formats.

Manufacturers include: 3M, Bostik, FastenMaster, Henkel LOCTITE, Power Adhesives, Surebonder

Handheld Hot Melt Gun Advantages

- Reliable and easy to use

- Easily portable

- Precise temperature

- Quick to warm-up

Design your hot melt production system with expert advice