The Practical Abilities of Spray Adhesives

Anyone who uses spray adhesives knows why they’re a go-to solution. Point, spray, press, and done — no nails or mess.

But as emissions regulations change, so do sprays, prompting trade-offs between compliance and performance. In this article, we’ll discuss how standards are changing and explore a new method to meet them.

Why Professionals Reach for the Sprayer

The popularity of spray adhesives boils down to three practical benefits that professionals experience every day:

Time is money, and spray can save both. A single worker can cover large areas and easily reposition pieces in minutes rather than painstakingly placing individual pins and screws. When dealing with tight deadlines and labor shortages, that translates right into the bottom line.

Even distribution creates superior bonds. Unlike the concentrated stress points created by nails or screws, spray adhesives distribute force across the entire bonded surface. This even distribution not only creates stronger bonds but may also eliminate issues like squeaking floors or rattling panels—particularly important in specialty vehicle applications like RVs where vibration is constant.

Versatility across materials. From porous insulation to non-porous metals, fabrics to fiberglass, spray adhesives bond diverse materials that would otherwise require different fastening methods. This versatility simplifies inventory and training while ensuring consistent results.

The VOC Challenge:

When Convenience Meets Regulation

Despite their practical benefits, traditional spray adhesives have faced increasing scrutiny due to their environmental impact and potential health concerns. A key issue? Volatile organic compounds, or VOCs.

VOCs can react with nitrogen oxides in the presence of sunlight, contributing to smog formation and respiratory problems. Inside buildings and vehicles, VOC emissions can impact indoor air quality long after application.

Over the years, regulations have reduced the allowable levels of VOCs in products like adhesives. This has led to countless reformulations and product changes, but it’s also aided in creating safer workplaces and cleaner environments.

Since the 1990s, California’s Air Resources Board (CARB) has led the charge in reducing allowable VOCs in adhesives. Other states in New England, the Mid-Atlantic, and Great Lakes regions have followed suit with their own regulations.

The regulatory trend is clear: allowable VOC limits continue to decrease. In 2017, CARB regulations reduced acceptable limits for mist-type aerosol adhesives from 65% to 30% by weight, and web spray adhesives from 55% to 40%. Manufacturers have been under mounting pressure to reformulate products while maintaining performance.

For businesses operating across multiple states, navigating this patchwork of regulations creates significant compliance challenges. Using different products in different regions increases inventory complexity and training requirements, while risking costly violations if the wrong product is used in a restricted area.

Adhering to these standards with a single solution that can work across different regulations, without compromising on effectiveness, has become a key goal for the next generation of spray adhesives. Maintaining these standards goes past environmental safety, too — maintaining low VOCs can improve worker comfort.

Previous Solutions:

Close But Not Quite There

Amid new regulations, the adhesives industry has responded with various approaches to address VOC concerns, but each has often come with significant trade-offs.

Traditional low-VOC formulations, especially when regulation first arose, often sacrificed performance for compliance. Early water-based alternatives dried slowly and sometimes didn’t hold up in demanding applications. Many contractors may have experienced the frustration of adhesives that seemed to work initially but failed prematurely under stress or moisture exposure.

3M™ Fastbond™ Pressure Sensitive Adhesive 1049:

Rethinking Spray Adhesives

An Optimized Application Method

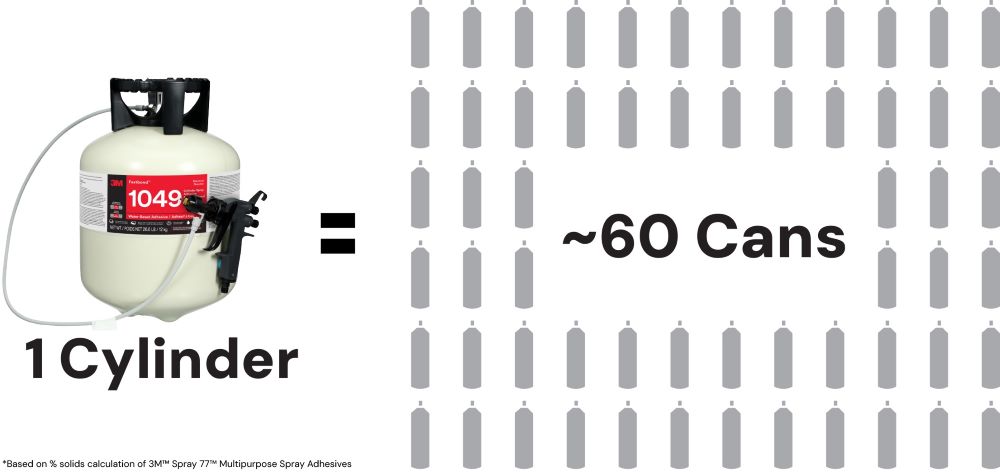

The first thing users may notice about 3M™ Fastbond™ Pressure Sensitive Adhesive 1049 is its optional cylinder delivery system. Unlike traditional aerosol cans that quickly end up in landfills, this portable, self-contained system significantly reduces waste—one cylinder effectively replaces approximately 60 aerosol cans. Beyond streamlining job site supplies, the cylinders are easy to use with a handheld spray system.

For applications not requiring a spray method, these adhesives are also compatible with traditional methods such as rolling.

Water-Based Doesn’t Mean Watered Down

The water-based formulation of 3M™ Fastbond™ Pressure Sensitive Adhesive 1049 delivers lower VOC emissions without sacrificing performance. Fast-drying and engineered for strong bonds, it effectively replaces mechanical fasteners like stick pins, insulation fasteners, and stud welding pins—saving time while increasing productivity.

For businesses concerned about regulatory compliance, this pressure-sensitive adhesive also meets the requirements of the California Air Resources Board (CARB), South Coast Air Quality Management District (SCAQMD), and the Ozone Transport Commission (OTC). This comprehensive compliance simplifies inventory management for companies operating across multiple jurisdictions.

3M™ Fastbond™ Pressure Sensitive Adhesive 1049

Construction:

Higher Building Standards Without Sacrificing Performance

The construction industry especially is under pressure to meet regulations while maintaining tight schedules. Traditional solvent-based sprays cause compliance headaches and mechanical fasteners are costly, yet alternatives often fall short.

3M™ Fastbond™ Pressure Sensitive Adhesive 1049 offers a smarter solution to help meet sustainability goals whether bonding waterproof membranes below-grade or affixing insulation. Its easy repositioning cuts damaging rework, while the portable cylinder simplifies workflows.

Marine Industry:

Battling Moisture While Meeting Environmental Standards

The marine environment presents unique challenges—constant moisture, salt exposure, and strict environmental regulations for waterways. Traditional mechanical fasteners can create potential leak points in hulls and decks, while many adhesives fail under marine conditions.

3M™ Fastbond™ Pressure Sensitive Adhesive 1049’s water-resistant bond makes it ideal for securing floor coverings, wall panels, and insulation in marine applications. Its low VOC content helps boatbuilders comply with increasingly strict emissions standards for marine manufacturing, particularly important for facilities near protected waterways.

Specialty Vehicles:

Where Weight and Air Quality Matter

From RVs to emergency response, specialty vehicle makers face tough choices when selecting a high performing adhesive that meets VOC regulations. Traditional stick pins and fasteners waste time during install and create potential rattle points, but conventional sprays can complicate sustainability goals.

3M™ Fastbond™ Pressure Sensitive Adhesive 1049 provides water-based bonding with immediate repositioning for panels, flooring, and insulation — enabling faster assembly and aiding sustainability goals.

HVAC and Industrial Equipment:

Performance Under Temperature Extremes

HVAC and industrial equipment need efficient installation of insulation and fabric in a way that maintains integrity under temperature cycles and vibration. But traditional pins and screws slow production, create failure points, and lead to waste from positioning errors.

3M™ Fastbond™ Pressure Sensitive Adhesive 1049 delivers aggressive tack for one-surface bonding and easy repositioning that prevents tears and eases rework. Plus, its permanent bonds eliminate clunky fasteners.

The Bottom Line:

Efficiency Without Compromise

By delivering the practical benefits that made spray adhesives popular and addressing the regulatory challenges that make them difficult, 3M™ Fastbond™ Pressure Sensitive Adhesive 1049 represents a significant advancement in spray adhesive technology.

For businesses navigating increasingly strict VOC regulations while facing pressure to improve efficiency, 3M™ Fastbond™ Pressure Sensitive Adhesive 1049 offers a solution that doesn’t require compromise. Its innovative cylinder delivery system, water-based formulation, and strong bonding performance create a win-win-win for productivity, worker safety, and environmental responsibility.

As regulations continue to evolve and sustainability becomes increasingly important, solutions like 3M™ Fastbond™ Pressure Sensitive Adhesive 1049 demonstrate that environmental responsibility and operational efficiency can go hand in hand—a practical path forward for industries that depend on reliable, efficient bonding solutions.