Improving Adhesives & Application Processes for Electric Vehicles

Improved adhesive technologies are the key to unlocking the promise of an electric future. Electric vehicles offer a wide range of production challenges, and Ellsworth Adhesives is uniquely positioned to help manufacturers build better, more cost-efficient EVs. We offer advanced adhesive solutions and application systems for EV assembly lines. This white paper outlines our EV-specific offerings.

Electric Vehicle Manufacturing

Adhesives in EVs need to:

- Withstand harsh environments with ranges of temperatures and moisture levels

- Endure extreme operating conditions including shocks and vibrations

- Provide high reliability and fail-proof operation

Adhesives in EV production need to:

- Facilitate rapid assembly

- Apply quickly and easily to surfaces with good flow, wetting, and adhesion

- Cure with a high-degree of repeatability

Electric Vehicle Adhesive Applications

When used in EV electronics, adhesives require dielectric strength and high thermal conductivity, all while retaining thermal stability. We offer strong-bonding adhesives, sealants and coatings for use in:

POWER ELECTRONICS

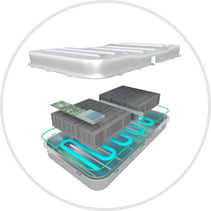

BATTERY PACKS

ADAS

E-MOTORS

Images courtesy of Dow Chemical Company.

Read this white paper to learn about how adhesives meet these challenges and the different types of adhesives available. Furthermore, learn about automated adhesive dispensing technologies custom-built for vehicle assembly lines and how Ellsworth Adhesives helped one customer achieve success.