Issue #14 - Fast Adhesives with Low Read Through

04/27/2016

April 28, 2016

April 28, 2016

Solution for Distorted Substrate Surface

Bob Zweng & Matt Ryan - Lord Corporation

Many aesthetically sensitive applications like sign assembly, kiosk design, cladding panels, and vehicle manufacturing are assembled with thin-gauge materials (composite or metal) and risk surface distortion. Substrate surfaces become discolored or distorted due to a cured bond line called Bond Line Read-Through (BLRT).

Read-through concerns are growing more common as manufacturers switch to thinner-gauge, composite substrates as a replacement for steel components and as a means to save on assembly costs and provide lighter-weight products. As requirements change for conditions such as light-weighting, longevity and quality - and a mixture of new substrate materials become more popular - manufacturers have begun to rely more on adhesives for bonding.

In one application, a utility trailer manufacturer had a major quality issue with sidewall distortion. Although the customer had switched from rivets to adhesives several years ago and enjoyed measurable benefits with reductions in assembly costs, plus significant improvements with water-leak warranty issues, the desire to have a smooth, read-through-free sidewall appearance was not met. The manufacturer struggled with various remedies and initially thought the only solution was to increase the panel thickness to prevent distortion. However, when the trailer builder s witched to using a low read-through adhesive, the distortion problem was solved.

A unique adhesive material was developed to alleviate the read-through problem that occurs when the adhesive can be seen through the substrate. Adhesive parts bonded with thin-gauge materials (composite or metal) can suffer from this type of surface distortion problem. Final “Class A” surface appearance/aesthetics are critical to many industrial and automotive OEMs and as a result adhesive bond-line read-through is not acceptable when working to achieve a world-class finish.

In 2015, LORD Corporation launched an exciting, new acrylic adhesive designed to eliminate the growing probability of thin panel distortion, also known as read-through. During the past year, into 2016, multiple customers in a variety of industries including construction and transportation markets have implemented this adhesive with overwhelming success.

Requiring little or no substrate preparation for bonding metals and plastics, this adhesive solution remains in position without sag when applied on vertical or overhead surfaces, allowing for greater process flexibility. Offering great environmental resistance, the system has proven to resist dilute acids, alkalis, solvents, greases, oils and moisture. Further, it also offers excellent resistance to UV exposure and weathering. The adhesive provides 8-12 minutes of working time and reaches handling strength in 20-25 minutes at 70°F (21°C). Mating surfaces must be held in contact and fixtured until handling strength is reached. Full cure is realized in 24 hours at room temperature. Cure rate can be accelerated by applying modest heat [<150°F(<66°C)].

When cured with LORD Accelerator 20, LORD 810 LRT Acrylic Adhesive creates a flexible system for bonding metals, such as aluminum, galvanized steel and CRS, as well as engineered plastics such as fiberglass, PC-ABS and ASA. The adhesive system delivers fast cure speed and strong bonding with little to no bond-line read-through (BLRT). LORD Accelerator 20 allows precise control of the adhesive bond-line thickness due to its content of glass beads.

LORD 810/20 acrylic adhesive is available in 400 mL, 200 mL, 50 mL, 5 gallon pails, and drums, the mixed adhesive bonds to surfaces using a handheld cartridge or automatic meter/mix/dispense equipment.

For more product information, click here

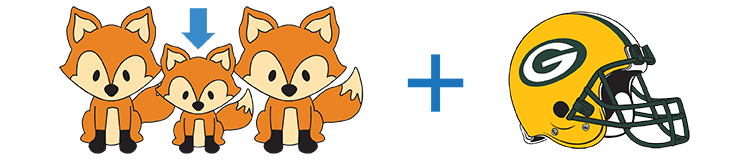

Pictogram Puzzle

A puzzle describing related products, applications, etc. The answer can be found at the bottom of the newsletter. Enjoy!

Upcoming Event

Consumer Electronics: Designing with Flexibility for Reliability

Hosted by Ellsworth Adhesives & Dow Corning

Date: Wednesday, May 11, 2016

Time: 02:00 PM EDT

Duration: 1 hour

From small wearable devices to large display screens, consumer electronics is one of the largest segments in the manufacturing industry. With ever-evolving technology and demands,

engineers are challenged to design lighter, thinner and more reliable electronics.

Attend this webinar to learn:

- Needs of consumer electronics design engineer

- Flexibility

- Product design examples

- Repairability and re-workability options in consumer electronics

Register here

Shipping on Carrier Account @ ellsworth.com

Our customers can now ship on their carrier account when ordering products on ellsworth.com.

Customers can enter their UPS or FedEx carrier account details during the checkout process, plus save it in their account information for faster future purchases.

Learn more now

Pictogram Puzzle Answer:

KitPackers

KitPackers offers custom packaging for adhesives, sealants and specialty chemical manufacturers and other adhesive and sealant users and resellers. A variety of formats for repackaging can be selected including MixPac cartridges (Sulzer MIXPAC), Semkits (Semco), Techkits (Techcon), ratio-paks, duo-paks, single component cartridges and syringes.

Discover more about KitPackers here.

Not a subscriber? Sign up for Bond Lines, our monthly eNewsletter, and get the latest industry news in your inbox.