Issue #7 - Process Prosperity

10/02/2015

September 3, 2015

September 3, 2015

Process Improvements Through Process Mapping

Jason McGough - Engineering Sales Representative

There comes a point in our day to day work lives where we step back and look at how to do things differently to increase output and improve time management. The same can be said for production lines in manufacturing facilities. Process mapping is a tool which can make organizations more efficient. They can be as simple as a step by step list or can include diagrams and flowcharts. The end goal is to improve the process, thus saving time and money.

One of the main objectives of process mapping is to eliminate unnecessary steps on a production line, and also aids in uncovering quality and employee issues, duplicate processes, and poor or outdated systems. Process improvements can be as simple as moving a trash can closer to the line, eliminating the use of a certain product and choosing another with less steps, or switching old technology for new, improved, or automated technology.

Process maps are helpful to current and new employees to see how a production line is run. They can be posted at each work station and referred to when questions arise. At the same time, workers on the front lines can be the most important part in getting the most out of a process map. A simple interview with each worker can give insight and ideas on how to make improvements. Who better to ask than the person actually doing the work every day?

But at what cost does process mapping have to an organization? It is important to understand the value proposition to determine the true cost savings. Changing procedures, materials, or technology has a cost. Process mapping compares the old and new processes to determine the steps eliminated or areas of improvement. Any costs are offset by savings when applied properly to appropriate types of processes.

Image a backlog or bottleneck in one of your manufacturing processes. How can you speed up your W.I.P.? Today’s new products and technologies aid production processes, such as faster curing adhesives, state of the art dispensing and custom packaging. As a result, some production steps could be eliminated and that time could be dedicated to doing something more productive. In turn, your organization is saving much more money than the extra cost in a new product or technology.

Process mapping coupled with continuous improvement is an opportunity to uncover hidden waste and improve operational efficiency. Leveraging innovative products and technologies paired with technical expertise are ways by which we can assist you and your organization achieve maximum cost savings.

Webcast:

Replacing PVC in the Medical Disposable Manufacturing Market

Date: Wednesday, September 16, 2015

Time: 10:00AM - 11:00AM CST

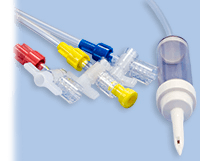

Ellsworth Adhesives is proud to partner with Henkel Loctite in the presentation of "Replacing PVC in the Medical Disposable Manufacturing Market," a webinar focused on the use of PVC alternatives in the design and manufacturing of disposable medical devices.

Ellsworth Adhesives is proud to partner with Henkel Loctite in the presentation of "Replacing PVC in the Medical Disposable Manufacturing Market," a webinar focused on the use of PVC alternatives in the design and manufacturing of disposable medical devices.

This free, one hour webinar event will highlight these advancements and introduce adhesive developmental achievements in this area.

NEW PRODUCT

Fisnar DC200

The Fisnar DC200 is a digital dispenser and valve controller that features a large internal air solenoid, perfect for applications that require immediate and fast reaction or de-pressurization while dispensing more viscous materials.

Click here for additional product details

Not a subscriber? Sign up for Bond Lines, our monthly eNewsletter, and get the latest industry news in your inbox.